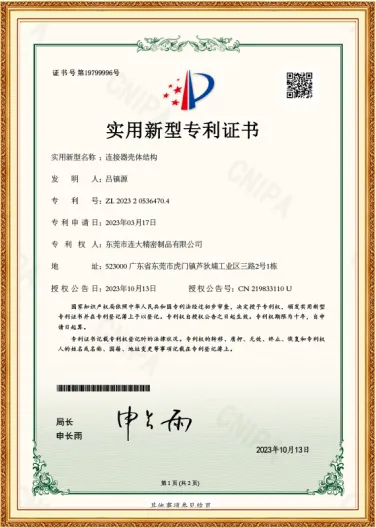

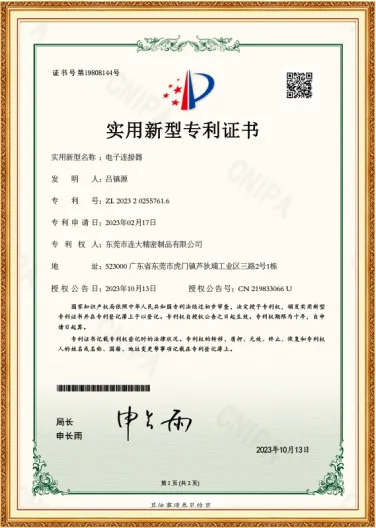

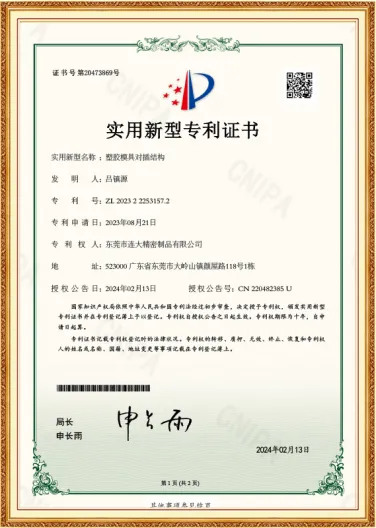

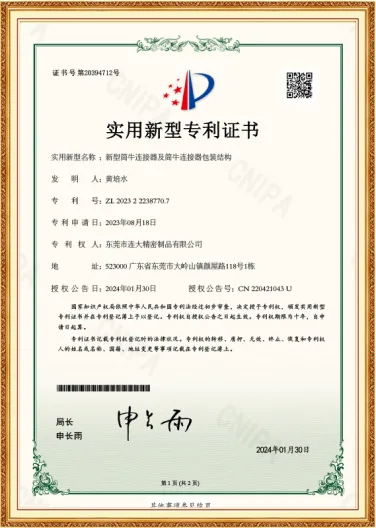

Professional R&D and Manufacturing Experience

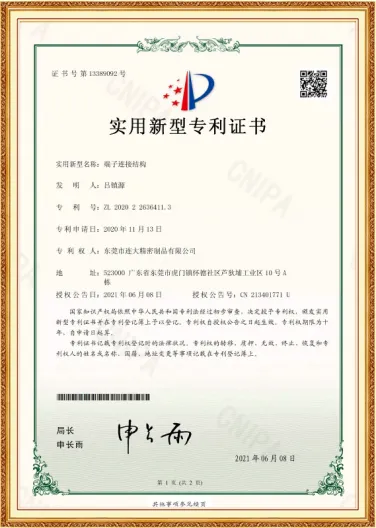

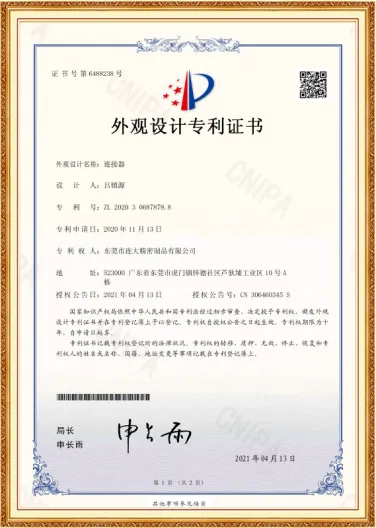

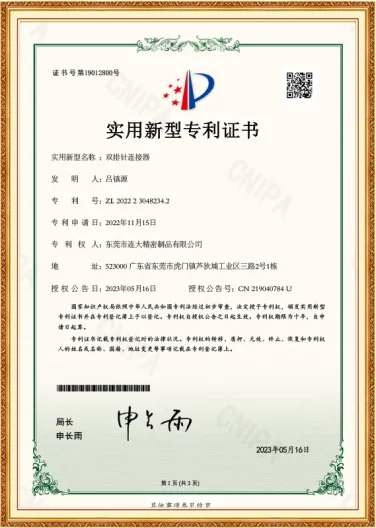

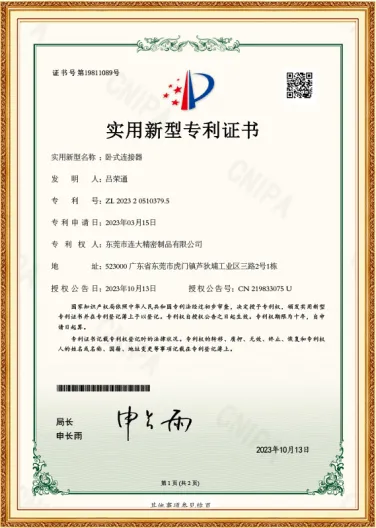

Since its establishment in 2006, the company has adhered to the principles of independent research and development, automated production, and intelligent testing, and independently completed the entire process from product development, mold design, processing, high-speed hardware stamping, plastic injection molding, surface plating, automated assembly and testing.

Factory Size And Equipment

The factory covers an area of 36,000 square meters and has more than 600 employees. The company has introduced a full range of complete mold processing equipment, including NISSEI and FANUC imported injection molding machines, YAMADA imported high-speed punches, and hundreds of sets of different types of precision plastic and hardware molds. The laboratory has passed CNAS national laboratory qualification certification, and has more than 400 fully automatic assembly, testing and packaging equipment. The daily production capacity can reach more than 10KKPCS. In order to cope with the increasingly severe international trade situation, a factory has been set up in Vinh Phuc Province, Vietnam in 2025, covering an area of 3,800 square meters, with more than 250 employees and 6 production lines.